Overview

Designed a web-based order pipeline for industrial robots to improve customer satisfaction and reduce support workload.

Challenge: Highly complex domain, no existing design system, and a previous internal team had failed to deliver. Goals were to simplify workflows, reduce support inquiries, and establish a scalable design foundation with KUKA branding.

Process

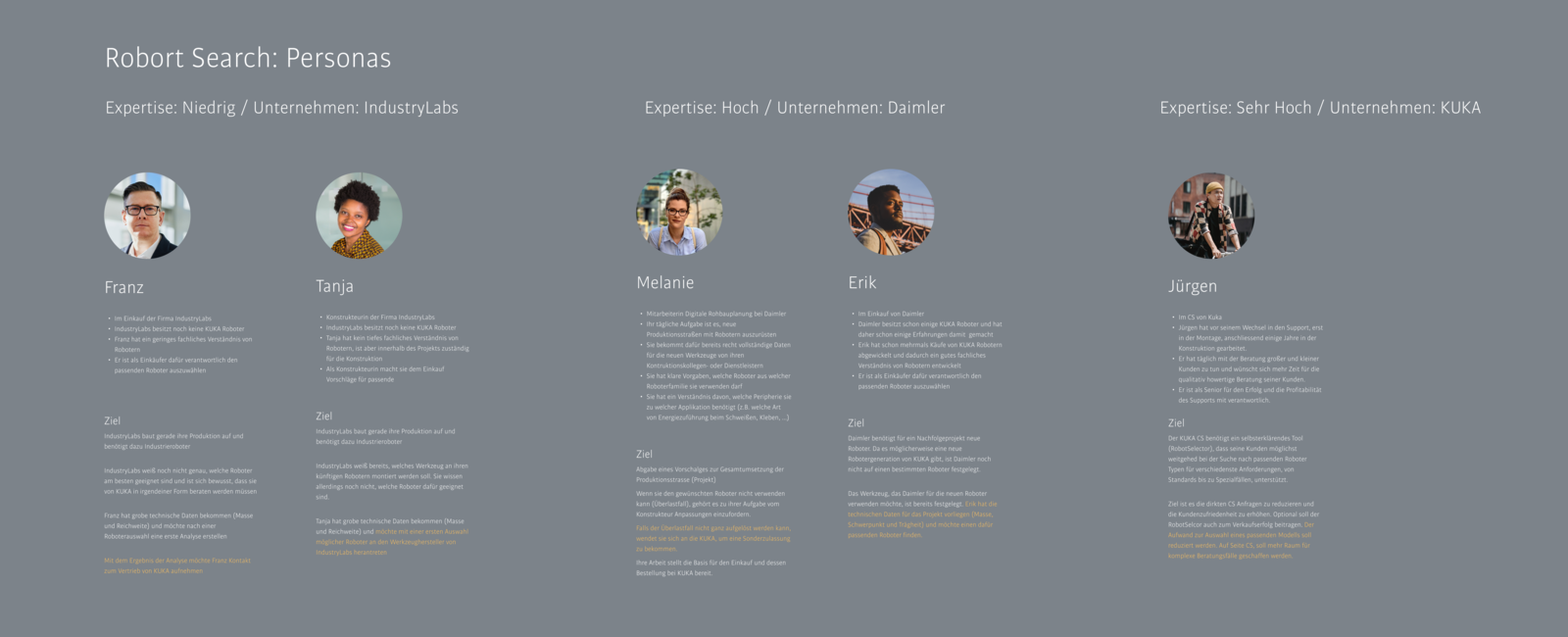

Domain & Personas

Learned the complex domain of industrial robots to ensure design decisions reflected real needs. Defined 5 personas: Franz (non-technical buyer), Tanja (construction manager), Melanie (production planner), Erik (experienced buyer), and Jürgen (KUKA support specialist).

Lo-Fi User Flows

Created low-fidelity flows for two primary use cases: robot identification and robot selection. Built prototypes to validate ideas and test usability early.

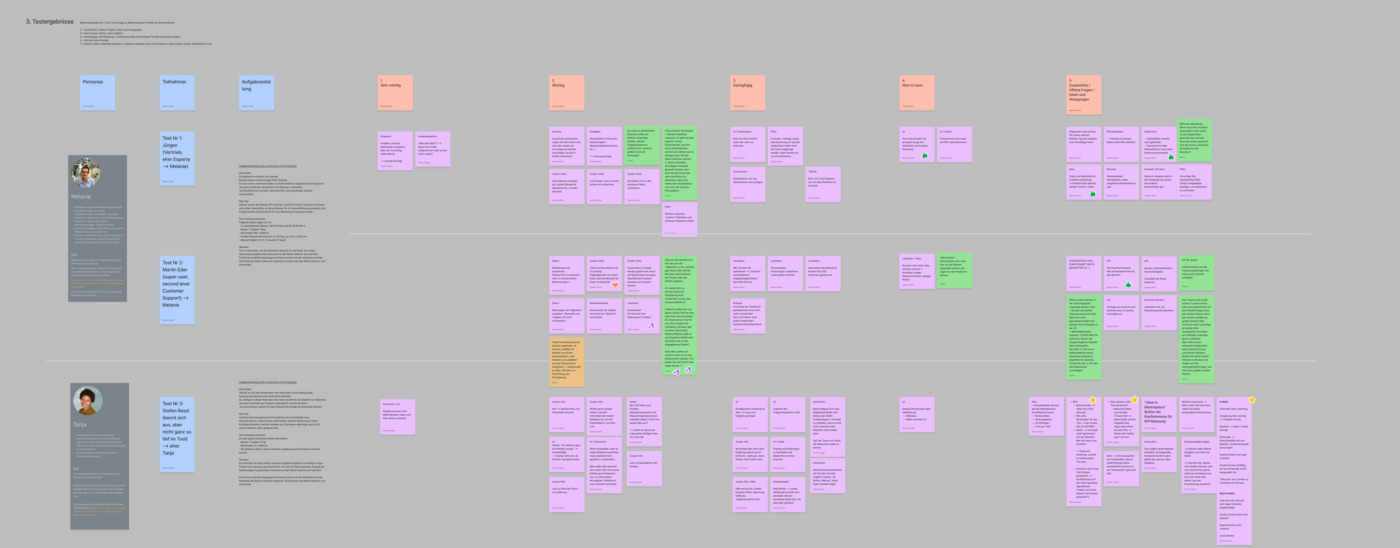

User Testing

Remote testing with 3 customer employees via video conference. Validated page structure, filters, navigation, and system status clarity. Measured with SUS scores and error rates.

Design System

Created custom design system based on atomic design principles. No existing framework, built from scratch for domain-specific needs. Modular components enabled flexibility and consistency.

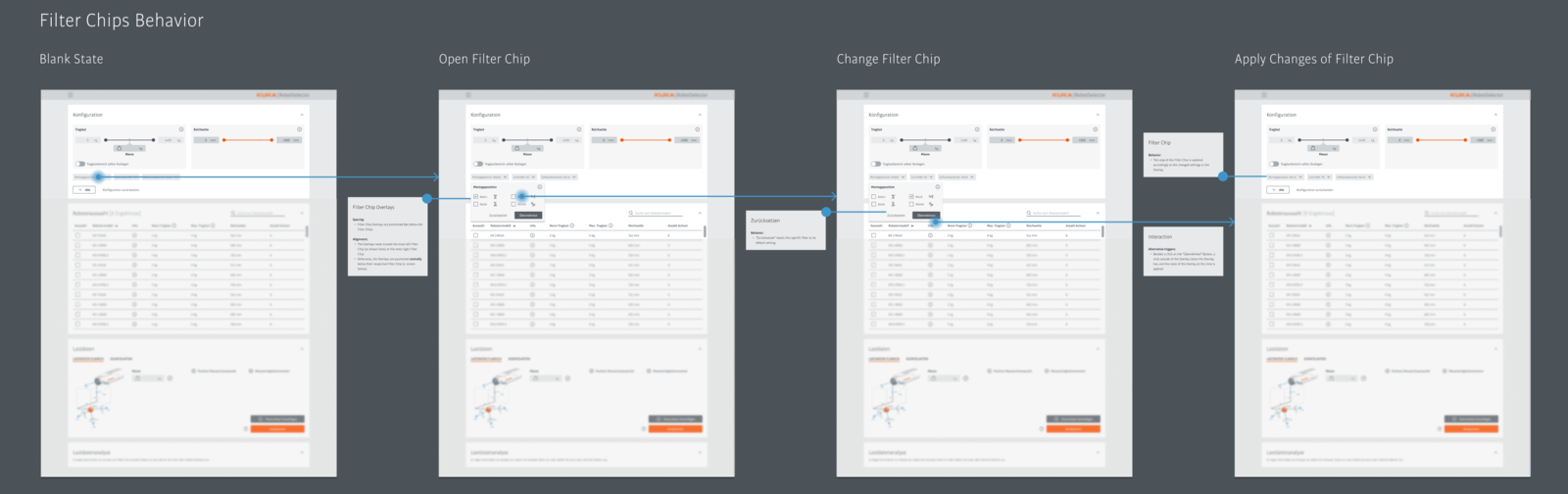

Hi-Fi & Handoff

All screens were handed off as high-fidelity user flows with detailed annotations. Each flow documented states, interactions, and edge cases, minimizing ambiguity for developers. In total, we delivered eight flows like the filter chip behavior shown below.

My Role

Led strategy and concept development, mentoring one junior designer. Conducted remote prototype testing and delivered production-ready screens. Main stakeholder contact, presenting progress and ensuring alignment.

Outcome

Delivered a user-friendly interface that simplified complex workflows. Results exceeded expectations, securing a second contract with KUKA.